|

Last update: 26.05.2022 |

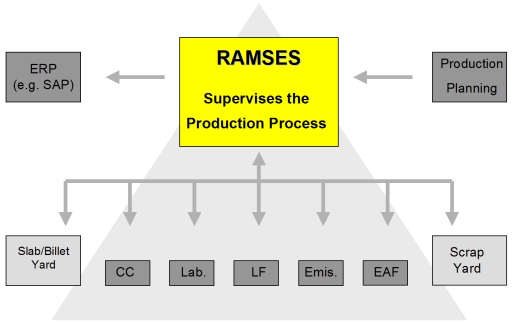

RAMSES for Meltshop A RAMSES Level 2 supervises the production process in the meltshop from the planning of the heats to the delivery of final products (slabs/coils/bars). All relevant data gathered in production is stored in the RAMSES data base, forwarded to high-level automation systems, and used for the automatic and manual generation of various types of heat reports.

A RAMSES Level 2 for the Meltshop has modules for the electric arc furnace, the ladle furnace, the continuous caster, the tracking of bars and the monitoring of the exhaust emissions. RAMSES is available with optional mathematical models. Typical models would be Thermal Models (temperature forecast, energy input control), Alloy Additions Calculation, Raw Materials Optimisation, Hardenabilty Calculation, Optimised Basket Loading Recipes, etc.

There are already many report types integrated into the standard version of RAMSES: Further report types can be integrated depending on the customer's requirements. The customer can define the layout of all screens and reports and the information to be displayed. There are several overview and detail screens showing production data of the Electric Arc Furnace, the Ladle Furnace, - if applicable - the vacuum degasser and the Caster. The (optional) ladle tracking module informs at any moment about ladle positions and stati. Also optional are the overview and detail screens for the tracking of bars and the monitoring of the emissions. Would you like to know more about RAMSES? |